A fully recyclable, innovative material—PDK may be the future of plastics10.05.2019

American researchers developed a new synthetic material than can be repeatedly recycled without any loss in quality.

The most frequently used plastics often include a bevy of additives, such as colorants or fillers, which tend to limit their recyclability potential. For example, only 20-30% of PET, the polymer used to produce plastic fibers and beverage packaging and widely considered one of the most recyclable materials, ends up being actually recycled. The rest ends up in waste incineration facilities and landfills, where they can linger for up to 100 years.

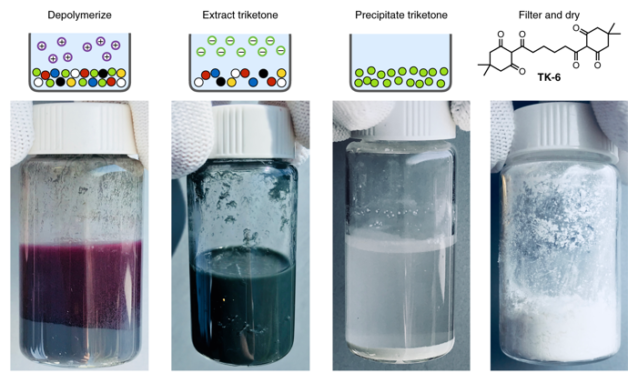

Researchers from Berkeley Lab's Molecular Foundry have recently announced a new development that may prove a groundbreaking achievement in the long run. Writing for Nature Chemistry, the team revealed the synthetic material they developed, called poly(diketoenamine) or PDK, can, unlike ordinary plastics, be recycled repeatedly and in a variety of ways. This highly innovative feature derives from its molecular structure—scientists can reassemble its individual components, called monomers. The monomers can be recovered by dunking PDK in a highly acidic solution, a process which breaks down the bonds linking monomers and separates them from the chemical additives used to determine its appearance and shape. The recovered monomers can then be reassembled into new polymers. These innovatively reclaimed plastics can then be recycled against and again, with different additives and thus different characteristics.

“Most plastics were never made to be recycled. But we have discovered a new way to assemble plastics that takes recycling into consideration from a molecular perspective”, said lead author Peter Christensen, a postdoctoral researcher at Berkeley Lab’s Molecular Foundry.

see also

- Kinga Syrek, the author of "Too Late": The art of discipline

People

Kinga Syrek, the author of "Too Late": The art of discipline

- Sophie Wang, the director of “Signal”: The film shouldn’t stay stagnant

Papaya Rocks Film Festival

Papaya Rocks Film FestivalPeople

Sophie Wang, the director of “Signal”: The film shouldn’t stay stagnant

- Aleksander Kropidłowski: In Search of Synthesis

Papaya Films

Papaya FilmsPeople

Aleksander Kropidłowski: In Search of Synthesis

- Łukasz Zabłocki: Creating parallel worlds

Papaya Films

Papaya FilmsPeople

Łukasz Zabłocki: Creating parallel worlds

discover playlists

-

Inspiracje

01

01Inspiracje

-

PZU

04

04PZU

-

Papaya Young Directors 6 #pydmastertalks

16

16Papaya Young Directors 6 #pydmastertalks

-

Original Series Season 1

03

03Original Series Season 1